Introduction

Whether you’re a beginner, an apprentice, or a seasoned professional, having the right resources is crucial to your success. In this article, we’ll explore the four most complete books that can help you prepare for a career in electrical installation, covering essential topics like electrical basics, safety, motor installation, wiring systems, and much more. These books are not only vital for certifications and exams but also serve as a handy reference for daily tasks in the field. Let’s dive into the key areas that these books cover and how they can help you become a top-notch electrical technician.

Electrical Basics

Before diving into more complex installations, every electrician needs to start with the basics. Understanding the fundamentals of electricity is a must-have foundation for any electrical technician. This is where books like Ugly’s Electrical References and Electrical Installations for Level 3 Apprentices come in handy.

Understanding Electricity Fundamentals

At the core of every electrical system, electricity flows through circuits, powering everything from light bulbs to industrial machines. But how does electricity actually work? Well, at its simplest, electricity is the flow of electric charge. This flow is measured by three primary properties: current, voltage, and resistance. Current is the flow of electrons through a conductor, voltage is the pressure that pushes the current, and resistance is the opposition to the flow of current.

Key Concepts: Current, Voltage, Resistance, and Power

- Current is the amount of charge flowing through a circuit, typically measured in amperes (A).

- Voltage is the potential difference that drives current through the circuit, measured in volts (V).

- Resistance opposes the flow of electricity, and it’s measured in ohms (Ω).

- Power, which is the amount of energy used by a device, is calculated as P = V x I (Power = Voltage x Current), measured in watts (W).

For an electrical technician, these terms aren’t just theoretical; they’re the building blocks for understanding everything from the smallest gadget to the most complex industrial installation.

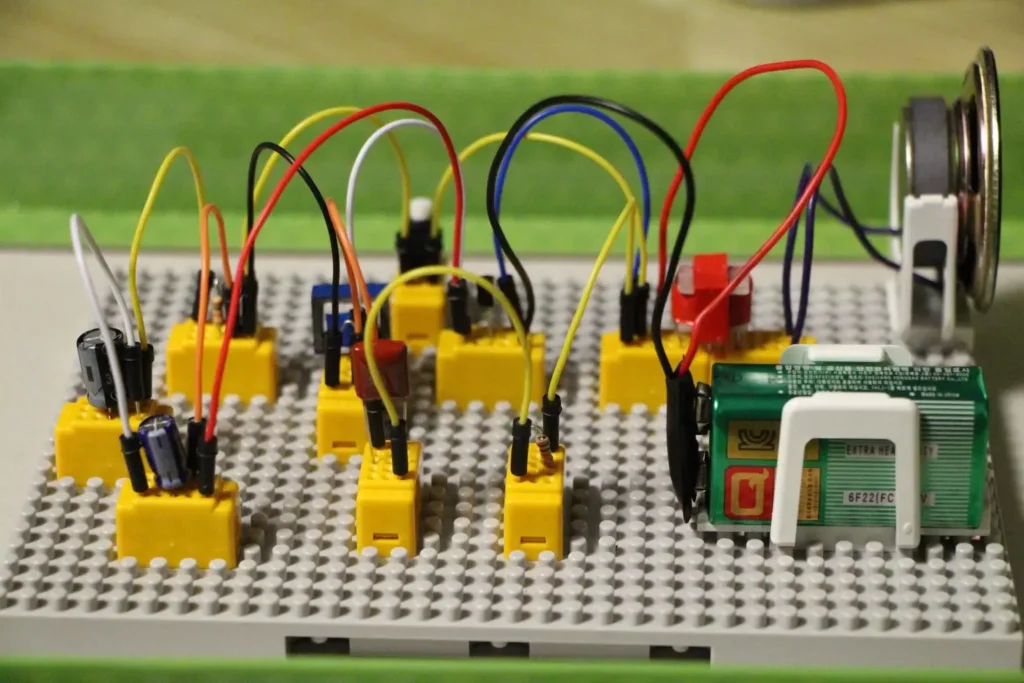

The Role of Circuits in Electrical Installations

Circuits are pathways that electricity follows to power various devices. There are two main types: series and parallel circuits. In a series circuit, the current flows through all components in a single loop. If you’re looking to adjust more content for active voice, the general rule is to keep the subject performing the action rather than being acted upon.

. In contrast, parallel circuits allow current to flow through multiple paths, so if one device fails, the others continue to work.

Understanding how circuits work is crucial when you’re troubleshooting issues or designing electrical systems for homes or businesses. Ugly’s Electrical References is particularly great for learning how to calculate the right wire sizes and understand how these circuits work in different setups.

By getting these electrical basics right, you’ll set yourself up for success in both the classroom and on the job. And as you progress, having a solid understanding of how circuits work will make you a more confident and capable technician.

Safety in Electrical Installation

Electrical work can be extremely rewarding, but it also carries significant risks. As an electrical technician, safety must always be the top priority. Every job, from basic wiring to complex installations, comes with potential hazards. Understanding the safety standards and regulations is essential to protecting yourself and others on the job. Luckily, there are comprehensive resources that walk you through proper safety practices, such as Ugly’s Electrical References and the IET Wiring Regulations.

Understanding Electrical Safety Standards and Regulations

Electrical safety standards are crucial for ensuring that installations are safe for both users and technicians. The National Electrical Code (NEC) and IET Wiring Regulations are the go-to sources that guide electricians on proper installation methods, from wiring systems to grounding techniques. The NEC provides specific guidelines on everything from circuit breakers to safety protocols, while the IET Wiring Regulations offer a detailed breakdown of compliance standards for the UK.

Personal Protective Equipment (PPE) and Safe Installation Practices

One of the key components of electrical safety is the use of proper personal protective equipment (PPE). Electrical technicians should always wear insulated gloves, rubber-soled boots, and safety goggles to protect themselves from potential shocks or flying debris.

Additionally, installation practices must emphasize grounding and insulation to prevent accidental contact with live wires. Working on a grounded system ensures that any stray currents have a safe path to the ground, reducing the likelihood of electrocution.

When handling electrical components, it’s also important to avoid shortcuts. For example, when working with cables and conduits, always use high-quality, compliant materials, and follow the correct installation procedures. Ugly’s Electrical References provides handy tables and safety tips for selecting the right wires, connectors, and grounding systems.

Linking to External Resources

For more on safety guidelines, the National Electrical Code (NEC) is an excellent resource to follow, as it lays out everything you need to know about maintaining safety during installations. For additional safety insights, visit the Electrical Safety Foundation International (ESFI) here.

Incorporating these safety practices into your routine will help you stay safe and confident, no matter the scale of the electrical project you’re working on.

Wires, Cables, and Conduits

In electrical installations, choosing the right wires, cables, and conduits is crucial to ensuring both functionality and safety. Whether you’re wiring a home, a commercial building, or setting up a factory, understanding the different types of materials and their uses is essential for any electrical technician.

Types of Wires and Cables

There are several types of wires and cables available, each designed for specific uses. For example, THHN (Thermoplastic High Heat-resistant Nylon-coated) wire is commonly used in residential and commercial buildings for general-purpose applications. Another popular wire is Romex, typically used in household electrical wiring for light fixtures, outlets, and appliances.

When selecting wires, you must consider the wire’s gauge, which refers to the thickness of the wire, and its voltage rating. A larger gauge wire can carry more current without overheating. The voltage rating tells you the maximum amount of electrical pressure the wire can safely handle.

Types of Conduits

Conduits are protective tubes that house electrical wiring, safeguarding it from physical damage and ensuring safe operation. The most common types of conduits include EMT (Electrical Metallic Tubing), PVC (Polyvinyl Chloride), and flexible conduit. EMT is often used for its durability and ease of installation, while PVC conduit is a great option for underground wiring due to its resistance to corrosion.

Best Practices for Installation

It’s important to choose the correct conduit for the specific environment. For instance, when running wiring outdoors, you’ll likely want to use weatherproof conduits. Additionally, always ensure that wires are properly sized and routed to prevent overheating and potential hazards.

For more detailed guidelines on how to choose the right cables and conduits, the National Electrical Code (NEC) is a helpful resource to follow.

These materials are the backbone of every electrical system, so knowing which to use and how to install them properly will set you on the right path to becoming an expert electrician.

Basics of Electric Motors Connection for Electric Motors

When it comes to the installation and operation of electric motors, proper connections are paramount. Making the right connections not only ensures the motor works efficiently but also safeguards against potential electrical hazards. As an electrical technician, having a strong understanding of how to connect electric motors correctly will be crucial for your daily work.

Types of Motor Connections

Electric motors use several types of connections, with the most common being the star (wye) and delta configurations. The choice of configuration affects the motor’s voltage, current, and power output.

- In a star connection, the motor windings connect in such a way that one end of each winding joins at a central point, often called the ‘neutral’ point. Technicians typically use this configuration for motors that need to operate at a lower voltage but higher current.

- In a delta connection, technicians connect each winding in a triangular shape, with the ends of the windings linked to the power supply.This connection allows for higher voltage operation but lower current than the star connection.

Key Considerations for Proper Motor Connections

When making motor connections, several key factors must be considered:

- Voltage Rating: Ensure the motor is connected to a power supply with the correct voltage rating. Incorrect voltage can lead to motor failure or inefficient performance.

- Phase Configuration: Whether the motor is designed for single-phase or three-phase power will affect how the connections are made. Three-phase motors are commonly used in industrial applications and offer more power, while single-phase motors are typically used in smaller household appliances.

- Protection Devices: It’s critical to install appropriate protection devices, such as fuses or circuit breakers, to prevent overloads and damage to the motor.

Installation Tips

To ensure a secure connection, always use high-quality connectors and tools. Use a megger to check the insulation resistance of the motor before finalizing the connection. This test ensures that no damage has occurred to the windings, preventing short circuits and other electrical issues.

Properly connecting electric motors not only ensures the longevity of the equipment but also guarantees the safety of everyone involved in the installation. For more details on wiring configurations, resources like Ugly’s Electrical References are invaluable, offering step-by-step guides on motor connections and best practices.

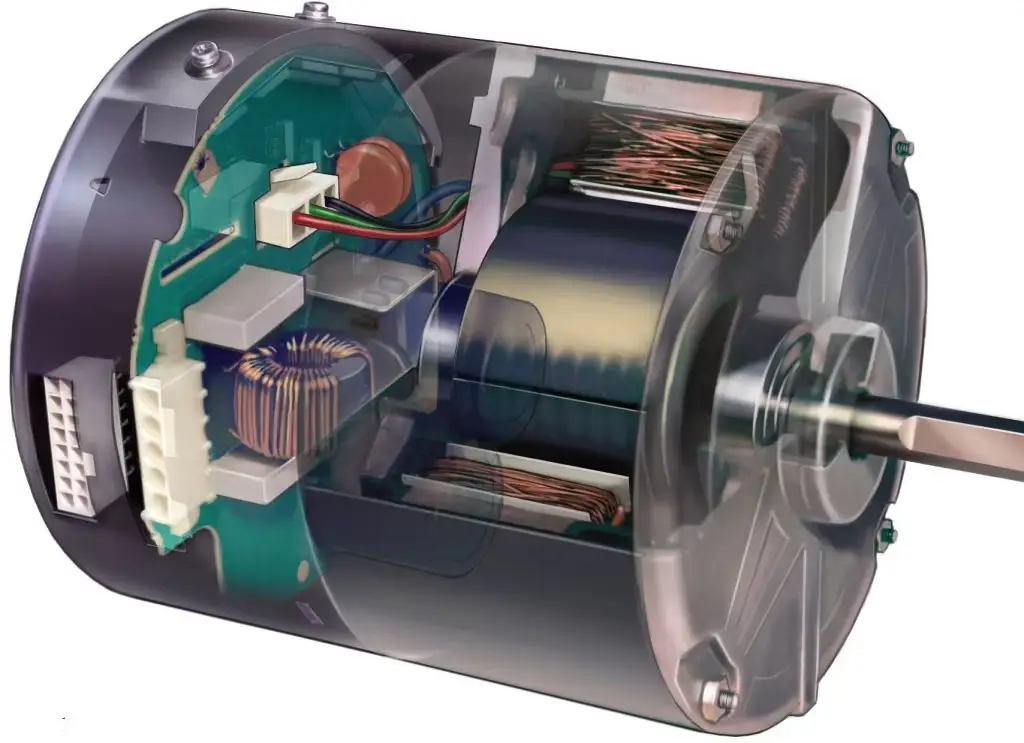

Electric motors are one of the most important components in modern electrical systems. Whether you’re powering small appliances or large machinery, understanding how motors work is vital for any electrical technician. Learning to maintain them is equally important. Books like Ugly’s Electrical References and Electricity for the Entertainment Electrician & Technician offer detailed explanations of motor systems. These books are indispensable for technicians in the field.

How Electric Motors Work

At their core, electric motors convert electrical energy into mechanical energy. They operate on the basic principle of electromagnetism: when electric current flows through a wire, it creates a magnetic field, which interacts with a magnet to create motion. The two most common types of motors are alternating current (AC) and direct current (DC) motors.

- AC motors are powered by alternating current, which changes direction periodically. They are commonly used in household appliances, fans, and industrial equipment.

- DC motors, on the other hand, run on direct current, which flows in one direction only. These motors are often used in devices requiring precise control, like electric vehicles and computer fans.

Key Components of Electric Motors

Regardless of the motor type, each motor has a few core components:

- Stator: The stationary part of the motor that generates a magnetic field.

- Rotor: The rotating part of the motor that interacts with the magnetic field to produce motion.

- Windings: Copper wires that carry electric current, creating the magnetic field in the stator and rotor.

Motor Applications and Troubleshooting

Electric motors are used in countless applications, from small appliances to large industrial machinery. Understanding the specific needs of a motor is crucial when installing or maintaining systems.

When troubleshooting electric motors, it’s important to diagnose common issues such as worn-out brushes, faulty bearings, or motor winding problems. A common test is to check the insulation resistance with a megohmmeter to ensure the windings aren’t shorted or damaged.

Learning how to properly size and connect motors, as well as troubleshoot common faults, is essential for every technician. Books like Electrical Installations for Level 3 Apprentices provide clear, detailed steps on diagnosing and fixing motor issues.

As you work with motors in various applications, always remember that proper installation and maintenance can prolong the life of the equipment, reduce energy consumption, and ensure smooth operation.

Installation of Electric Service Boxes and Panels

Installing electric service boxes and panels is a critical aspect of any electrical system. These components act as the central hubs that distribute electricity throughout a building. As an electrical technician, understanding how to install and wire service boxes and panels properly ensures both safety and functionality. Let’s take a closer look at what’s involved in the process.

Understanding the Purpose of Service Boxes and Panels

The electric service box, also known as a breaker panel or distribution board, serves as the primary control point for the electrical supply to a building. It receives power from the main supply line and distributes it to various circuits throughout the premises. The box contains circuit breakers, which automatically cut off the power if a fault or overload is detected.

The panel houses the breakers and connects the wires from each circuit. These panels vary in size based on the number of circuits they need to handle. Larger panels with more circuit breakers serve commercial buildings or larger homes, while smaller panels typically serve residential settings.

Steps for Proper Installation

- Choosing the Correct Location: The service box or panel should be installed in a dry, easily accessible location. According to the National Electrical Code (NEC), it should be placed in a spot that allows for safe operation, with enough clearance on all sides for maintenance and inspection.

- Sizing the Panel: The size of the panel should match the electrical demand of the building. The panel must have enough space for future circuit expansions, so it’s important to overestimate slightly. Common sizes range from 100 to 400 amps for residential homes.

- Wiring the Panel: Proper wiring is crucial to ensure the electrical system works efficiently and safely. Start by connecting the main incoming power supply to the main breaker, and then connect each circuit breaker to the corresponding wire. Be sure to use the correct wire gauge based on the current load and adhere to NEC guidelines.

- Grounding the Panel: Grounding is a critical safety measure to prevent electrocution. The panel should be properly grounded to the earth using a grounding electrode conductor (GEC), which connects to a grounding rod.

Testing and Final Checks

After installation, test the panel to ensure all connections are secure and each breaker functions correctly. Check the system with a voltmeter or multimeter to confirm the proper voltage levels.

Electrical Switches and Installation of Power Outlets

Electrical switches and power outlets are essential components of any electrical installation, allowing users to control the flow of electricity to various devices and appliances.

Types of Electrical Switches

There are several types of electrical switches, each designed for specific purposes:

- Single-pole switches: These are the most common type of switch found in homes. They control a single light or appliance from one location.

- Three-way switches: These allow control of a light from two different locations, commonly used in hallways or staircases.

- Four-way switches: These are used in conjunction with two three-way switches to control a light from three or more locations.

- Dimmer switches: These allow users to adjust the brightness of lights by controlling the voltage.

Switch Installation Tips

When installing electrical switches, it’s important to follow these best practices:

- Turn off the power: Always cut the power supply before beginning any work to prevent electrical shocks.

- Use the correct gauge wire: Make sure the wire gauge matches the electrical load for the switch. Overloading a switch can cause overheating and potential fire hazards.

- Proper grounding: Ensure that the switch box is properly grounded to prevent electrocution risks.

Installing Power Outlets

Power outlets are where electrical devices plug into the system, providing them with power. Several types of outlets exist, including GFCI (Ground Fault Circuit Interrupter) outlets, which are commonly installed in wet or damp areas like kitchens and bathrooms, and standard 120-volt outlets, which are used throughout most of the home.

Steps for Outlet Installation:

- Choose the location: The outlet should be placed at a comfortable height and in a location where it can be easily accessed.

- Connect the wires: When wiring an outlet, connect the black (hot) wire to the brass screw, the white (neutral) wire to the silver screw, and the green or bare (ground) wire to the green screw.

- Test the outlet: After installation, use a circuit tester to ensure the outlet is wired correctly and is functioning properly.

Circuit Maps and Projects in Facilities

As an electrical technician, one of the most important skills you’ll develop is understanding how to read and create circuit maps (also known as wiring diagrams). These diagrams visually represent how electrical systems are arranged within a building or facility, helping technicians ensure that each component connects correctly and safely.

Understanding Circuit Maps

Circuit maps are essential tools for visualizing the electrical layout of a building or facility. They provide the following:

- Circuit Identification: Maps show the exact route each wire takes and how it’s connected to outlets, switches, and appliances.

- Power Flow: Circuit maps help track how electricity flows from the service panel through the circuits to power various devices.

- Safety Checks: By reviewing a circuit map, you can identify potential issues, such as overloaded circuits or improperly connected wires.

The National Electrical Code (NEC) recommends that every electrical installation be accompanied by a well-detailed circuit map to ensure safety and compliance. These maps are useful not only for electricians but also for facility managers and inspectors who need to ensure proper installation.

Creating a Circuit Map

When creating a circuit map, there are several important steps to follow:

- Labeling Components: Start by labeling all major electrical components, including the service panel, switches, outlets, lighting fixtures, and major appliances.

- Indicating Power Source: Indicate the main power source, usually from the utility line, and show how it enters the building.

- Routing Wires: Draw lines representing the wires connecting components. Ensure the lines clearly show how circuits branch off and power different devices.

- Circuit Breakers: Include information about the specific breakers in the panel, which will correspond to each circuit’s load.

Importance of Circuit Maps in Large Facilities

In large commercial or industrial facilities, circuit maps play an even more vital role. These maps help electricians and engineers understand complex electrical systems, troubleshoot problems efficiently, and plan upgrades or expansions. The maps also assist in ensuring that installations comply with electrical codes, which is crucial for maintaining safety and avoiding penalties.

For project installations in new facilities or when performing upgrades, detailed circuit maps help technicians determine the most efficient way to route wires, place outlets, and connect equipment. Clear labeling and detailed symbols simplify the process and help ensure that technicians complete installations without error.

In facilities, project planning often includes electrical layouts. Understanding how to interpret and create circuit maps is a vital skill for any technician. Resources like Ugly’s Electrical References and The National Electrical Code (NEC) provide detailed guidelines for mapping electrical systems. These resources also ensure compliance with industry standards.

Repair Projects and Common Errors in Electrical Installations

As an electrical technician, your work doesn’t end with the installation of electrical systems. You will also be tasked with diagnosing and repairing electrical problems. Whether you’re working on a minor repair or addressing a serious fault, having the right tools, knowledge, and approach is essential for maintaining the safety and efficiency of electrical installations.

Common Electrical Repair Projects

Electrical repairs can vary widely depending on the issue at hand, but some of the most common repair projects include:

- Rewiring and Replacing Outlets: Over time, outlets can wear out, get damaged, or become outdated. Replacing old or faulty outlets is a common repair task. Technicians must ensure the correct wiring is used to prevent electrical shorts or overloading.

- Breaker Panel Repairs: If a circuit breaker trips frequently, it may be due to an overload, faulty wiring, or a defective breaker. Repairing or replacing circuit breakers is a job that must be done with caution, as mishandling can cause electric shock or fire hazards.

- Lighting Fixtures: Electrical issues in lighting systems are another common repair project. Broken switches, faulty light bulbs, or issues with the wiring in the light fixtures are frequent problems. Repairing these often involves checking for loose connections or replacing damaged parts.

- Electric Motor Repairs: Electric motors can suffer from wear and tear over time, leading to performance issues. Technicians often need to repair or replace motor components, including brushes, bearings, or windings, to restore functionality.

Identifying Common Electrical Errors

When installing or repairing electrical systems, mistakes can lead to dangerous situations. Understanding the most common errors can help technicians avoid costly and hazardous mistakes. Some of the most frequent installation errors include:

- Incorrect Wiring: One of the most common errors in electrical work is miswiring. This could involve reversing the hot and neutral wires or failing to properly ground a system. This mistake can lead to short circuits, electrical shocks, or even fires.

- Overloading Circuits: Installing too many devices on a single circuit can cause it to become overloaded. This not only puts a strain on the electrical system but can also lead to overheating, fires, or damage to appliances and devices.

- Poor Grounding: Improper grounding is a serious mistake that can lead to electrical shocks or equipment failure. Every electrical system should be properly grounded to reduce the risk of short circuits or electrocution.

- Loose Connections: Loose connections are another common error, leading to arcing or electrical sparks that can be both dangerous and destructive to equipment. These can occur when wires are not properly tightened or when insulation is damaged.

Repairing Errors

When repairing these common errors, technicians should use the appropriate tools, like a multimeter for testing connections, or a megger for insulation testing. Diagnosing and correcting these errors is essential to prevent further damage to electrical systems and ensure safety for everyone involved.

Home Automation and Automation in Electrical Installations

In today’s world, automation has become an integral part of both residential and commercial electrical systems. Home automation allows homeowners to control lighting, heating, security systems, and appliances remotely or automatically through devices like smartphones, voice assistants, or smart hubs. As an electrical technician, understanding how to install, configure, and troubleshoot these systems is an essential skill.

Understanding Home Automation

Home automation systems consist of interconnected devices that you can control centrally or remotely. These systems use technologies like Wi-Fi, Zigbee, Bluetooth, and Z-Wave, which enable devices to communicate with one another. A well-designed home automation system can improve energy efficiency, increase security, and enhance comfort by allowing users to control home functions with ease.

Common devices used in home automation include:

- Smart Thermostats: These devices learn the homeowner’s preferences and adjust the temperature automatically. They can be controlled remotely, allowing homeowners to save energy when they are away.

- Smart Lighting Systems: Smart bulbs and switches allow users to control lighting from their phones or set schedules. These systems often integrate with motion sensors, making the home more energy-efficient.

- Smart Locks and Security Systems: These allow homeowners to monitor and control access to their homes. Smart cameras, doorbells, and locks can be integrated into the system for enhanced security.

- Smart Appliances: Refrigerators, ovens, washers, and dryers that are connected to the internet can be monitored and controlled remotely, providing convenience and energy savings.

Installation and Wiring for Home Automation

Installing home automation systems involves more than just connecting a few devices to a Wi-Fi network. Electrical technicians need to integrate these devices into the existing electrical system, ensuring everything is connected safely and effectively.

- To properly power automation devices, ensure that each device receives sufficient voltage and is wired according to the manufacturer’s specifications. For instance, install smart switches into standard electrical boxes, and you may need to add extra wiring for certain devices.

- Central Hub Installation Some automation systems require the installation of a central hub or controller that connects all devices. This hub must be wired to the home’s network and powered securely.

- Safety Considerations: Electrical technicians must ensure that all wiring complies with the National Electrical Code (NEC), particularly when dealing with smart devices that may have specific electrical requirements.

Troubleshooting Automation Issues

As with any electrical installation, problems can arise with home automation systems. Technicians may face challenges such as connectivity issues, device malfunctions, or integration problems. Using diagnostic tools like multimeters to test power and connectivity, as well as using specific troubleshooting guides from manufacturers, will help resolve these issues.

Home automation is rapidly evolving, and staying updated with the latest trends and technologies is essential for electrical technicians to remain competitive in the field. Resources like Ugly’s Electrical References and the National Electrical Code (NEC) provide the guidelines necessary to navigate the complexities of these installations safely and effectively.

By mastering home automation installations and troubleshooting, you not only enhance your skill set but also improve the overall functionality and efficiency of modern electrical systems.

FAQs

What are the essential skills for an electrical technician?

Electrical technicians need a solid understanding of electrical systems, wiring, safety protocols, and troubleshooting. Key skills include the ability to interpret circuit maps, install and maintain electric motors, and ensure compliance with codes like the National Electrical Code (NEC).

What books should an electrical technician study?

Some of the best resources for electrical technicians include Ugly’s Electrical References and The National Electrical Code (NEC). These books provide comprehensive guidelines and detailed information on electrical systems, wiring, and safety standards.

Why is safety important in electrical installation?

Safety is crucial in electrical work to prevent accidents, fires, or electrical shocks. Proper wiring, correct tool usage, and adherence to industry standards like the NEC help ensure safe installations and maintenance.

How do I interpret circuit maps as an electrical technician?

Circuit maps show the layout and connections of electrical systems. Understanding these maps requires knowing the symbols used to represent various components like switches, outlets, and panels, as well as the pathways for electrical flow.

Conclusion

In conclusion, preparing as an electrical technician involves mastering a wide array of skills and knowledge that span across various technical and safety aspects of the trade. From understanding electrical basics like Ohm’s Law to delving into complex systems such as electric motor installations and home automation, each area is essential for building a well-rounded skill set.

Safety remains the top priority for every technician, with knowledge of proper wiring, correct use of tools, and adherence to National Electrical Code (NEC) guidelines ensuring safe practices in the field. Technicians must stay current with the latest technologies in smart devices and home automation systems, as these technologies become increasingly common in both residential and commercial settings.

Investing time in the right resources, such as industry-standard reference books like Ugly’s Electrical References, as well as hands-on experience, will equip you with the confidence and expertise to tackle any electrical project—from wiring new homes to troubleshooting advanced automated systems. This ongoing learning process not only enhances your technical capabilities but also helps you stay competitive in a field that’s constantly evolving.

Whether you’re working on a small repair or a large-scale electrical installation, having the foundational knowledge and skills in these key areas is crucial for success.Thorough training, hands-on experience, and an up-to-date understanding of the latest electrical innovations will prepare you for a rewarding and long-lasting career in the electrical field.