When it comes to electrical safety, few things are as crucial—and as overlooked—as grounding systems. These systems play a pivotal role in safeguarding your home, equipment, and, most importantly, you, from potential electrical hazards. In this article, we’ll break down everything you need to know, from the basics of what grounding is to step-by-step guidance on installation. By the end, you’ll not only understand grounding systems but also appreciate their role in creating a safer environment.

What Are Grounding Systems?

Grounding systems might sound technical, but at their core, they’re all about safety. Imagine this: an electrical fault occurs, and instead of wreaking havoc on your appliances—or worse, endangering lives—the excess current is redirected safely into the earth. That’s the power of grounding.

What Is a Grounding System?

A grounding system is essentially a backup pathway for electrical energy. When there’s a fault in your wiring, like a loose connection or short circuit, grounding offers the electricity an escape route—away from you and your appliances, and straight into the ground. This prevents overheating, reduces the risk of fires, and protects anyone who might come into contact with a live wire.

Why Are Grounding Systems Essential?

Grounding systems don’t just protect against faults; they also stabilize your electrical system. For instance, they limit voltage surges caused by lightning or sudden spikes in power, ensuring your devices aren’t fried. Moreover, they provide a consistent reference point for your electrical circuits, keeping things running smoothly.

The Risks of Poor Grounding

Without a proper grounding system, you’re flirting with danger. Electrical shocks, equipment damage, and even structural fires can result from ungrounded systems. It’s not just about adhering to codes—good grounding is about creating a secure living and working environment.

Real-World Applications of Grounding Systems

Grounding isn’t just for homes; it’s crucial in industrial settings, power plants, and even in protecting tall structures like towers and smokestacks. In every case, the principle remains the same: channeling unwanted electricity away from harm.

Pro Tip: Always ensure your electrical system adheres to National Electrical Code (NEC) standards. For more information, check out NEC Grounding Standards.

Basics of Grounding Systems

Understanding the fundamentals of grounding systems is the first step toward appreciating their value. From their key components to how they work, this section unpacks the basics that make these systems indispensable in electrical safety.

Definition and Purpose

At its simplest, a grounding system is a network of wires and components designed to redirect excess electrical energy safely into the ground. Electricity naturally seeks the easiest path to return to the earth, and grounding systems provide a controlled pathway to prevent erratic behavior, such as sparks or overheating.

But what’s the real purpose here? It’s all about balance. By stabilizing voltage levels in your electrical circuits, grounding keeps your appliances and devices running without hiccups—even during power surges. Plus, it’s a lifesaver when faults or malfunctions occur, channeling dangerous currents away from humans and pets.Components of a Grounding System

Every grounding system relies on a few critical components working in harmony:

- Grounding Electrode: A rod or plate buried deep in the earth, typically made from conductive materials like copper or galvanized steel. This is where the current ultimately dissipates.

- Grounding Conductor: A wire that connects the electrical system to the grounding electrode. Its job? To carry the fault current safely to the ground.

- Bonding System: Ensures all metallic parts of your electrical setup (like conduit pipes and metal enclosures) are connected, reducing the chance of stray electricity causing a hazard.

Did you know that even your metal water pipes could be part of the grounding system? This integration is especially common in older homes, where grounding wires often connect to plumbing systems to improve overall safety.

How Grounding Works

The mechanics of grounding are straightforward yet fascinating. When an electrical fault occurs, such as a surge or short circuit, the grounding conductor directs the excess energy to the grounding electrode. From there, it disperses harmlessly into the earth. This process not only protects individuals from electric shocks but also shields connected equipment from damage.

Here’s an analogy: think of a grounding system as a pressure relief valve for your electrical circuits. Without it, the “pressure” (electricity) has nowhere safe to go, leading to dangerous outcomes like sparks or overheating.

Pro Tip: Ensuring your home’s grounding is up to modern standards is essential. Many older homes lack proper grounding, so consider hiring an electrician for a thorough check-up. For more residential safety tips, visit Electrical Safety Foundation International.

Types of Grounding Systems

Not all grounding systems are created equal! Depending on the environment and specific needs, different types of grounding are used to ensure electrical safety and efficiency. This section covers the main types of grounding systems, helping you understand which might be best suited for various applications.

Solid Grounding

In solid grounding, the neutral point of the system is directly connected to the ground without any resistance or impedance. This approach ensures that fault currents flow easily into the ground, minimizing overvoltage risks.

- Advantages: Simple to design and implement, and it limits transient overvoltages effectively.

- Common Uses: Found in industrial and commercial settings where safety and reliability are critical.

However, this type of system may result in higher fault currents, which can increase stress on the electrical infrastructure.

Ungrounded Systems

As counterintuitive as it sounds, ungrounded systems aren’t physically connected to the ground. Instead, grounding is achieved through the natural capacitance of the equipment.

- Advantages: Prevents system-wide shutdowns during the first fault and is less prone to voltage disturbances.

- Disadvantages: Faults can go unnoticed for extended periods, potentially causing severe damage.

- Common Uses: Industrial applications where continuous operation is a top priority, such as in manufacturing plants.

Low Impedance Grounding

In low impedance grounding, a resistor is connected between the neutral point and the ground. This setup limits the fault current to a manageable level while still offering grounding benefits.

- Advantages: Reduces equipment damage by controlling fault currents.

- Disadvantages: More complex and costlier than solid grounding.

- Common Uses: Ideal for high-voltage systems or critical infrastructures, such as power plants.

High Impedance Grounding

Similar to low impedance grounding, but with a higher resistance value, high impedance grounding limits fault current even further.

- Advantages: Provides precise control over fault currents, reducing arc flash hazards.

- Disadvantages: May require specialized equipment and maintenance.

- Common Uses: Used in sensitive systems, like data centers, where minimizing electrical disturbances is crucial.

Specialized Grounding Systems

Beyond these primary types, there are specialized grounding systems designed for unique scenarios:

- Lightning Protection Grounding: Directs lightning strikes safely into the ground, protecting buildings and equipment.

- Static Electricity Grounding: Used in environments like chemical plants or fueling stations to prevent dangerous static buildup.

Each system has its strengths and is tailored to specific needs, making it essential to choose the right type for the intended application.

Pro Tip: To dive deeper into technical details on grounding systems, visit EE Power Grounding Basics.

How to Install Grounding Systems

Installing a grounding system may seem like a daunting task, but with proper preparation and attention to detail, it can be done effectively and safely. Whether you’re working on a new installation or upgrading an older system, this step-by-step guide will help you navigate the process.Planning and Preparation

Before you dive in, it’s crucial to plan your project carefully.

- Assess the Site: Start by evaluating the soil conditions, as soil conductivity plays a significant role in grounding effectiveness. Moist, loamy soils are ideal, while sandy or rocky terrain might require additional measures.

- Select Materials: Choose high-quality materials like copper grounding rods or plates for better conductivity and durability. Opt for corrosion-resistant options to ensure longevity.

- Understand Local Codes: Familiarize yourself with the National Electrical Code (NEC) or your country’s standards to ensure compliance. Grounding systems must meet specific requirements to guarantee safety.

Installing Grounding Electrodes

Grounding electrodes are the heart of any grounding system. Here’s how to install them:

- Locate the Grounding Point: Identify a spot close to your electrical panel and free of underground utilities like water pipes or cables.

- Drive the Electrode Into the Ground: Using a hammer or power driver, insert the rod at least 8 feet into the earth. For rocky areas, use a plate electrode or multiple shorter rods connected together.

- Ensure Proper Depth: The deeper the electrode, the better the contact with moist soil, improving the system’s effectiveness.

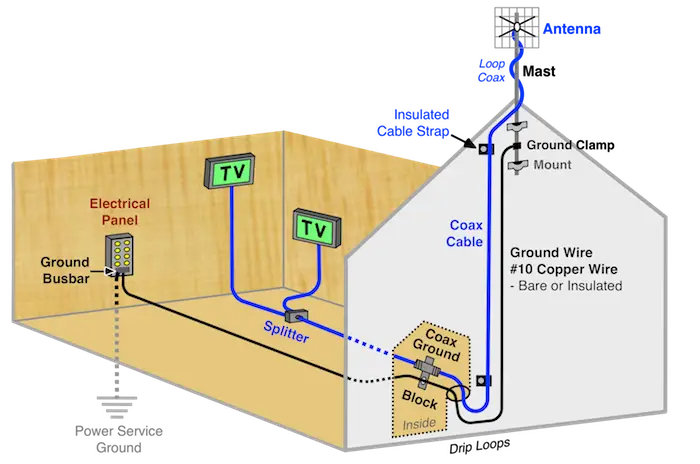

Connecting the Grounding Conductors

With the electrode in place, it’s time to connect it to the electrical system.

- Use a Grounding Clamp: Secure the conductor to the electrode using a heavy-duty grounding clamp. Ensure the connection is tight and free of corrosion.

- Route the Conductor: Run the wire to the main service panel, keeping it protected in a conduit to avoid damage.

- Bond to the Neutral: Connect the grounding conductor to the neutral bar in your service panel. This completes the pathway for excess electricity to flow safely to the ground.

Testing and Verifying the Installation

Once everything is set up, testing ensures the system is functioning properly.

- Perform a Ground Resistance Test: Use a ground resistance tester to measure the system’s impedance. A reading of 25 ohms or less is ideal, as recommended by the NEC.

- Inspect for Continuity: Verify that all connections are secure and there are no gaps in the bonding system.

- Conduct a Fault Simulation: Simulate a fault to check if the system directs excess current safely to the ground.

Safety Tips

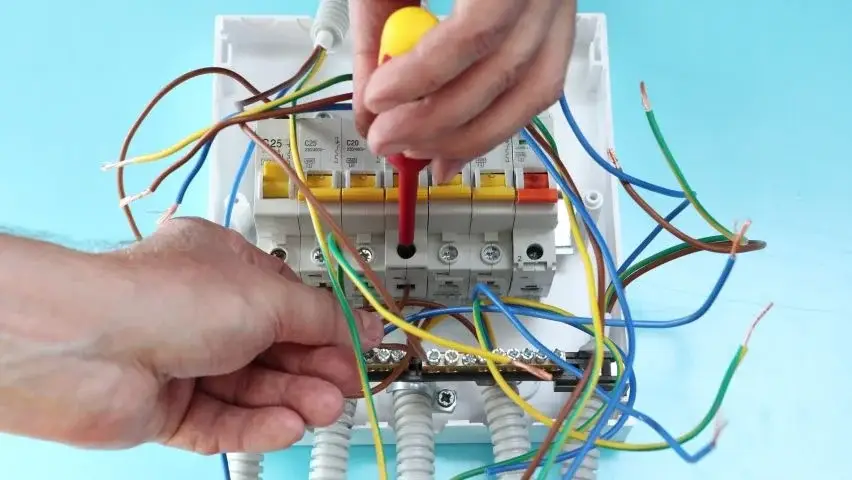

- Always turn off the power at the main breaker before working on the electrical system.

- Wear insulated gloves and use tools rated for electrical work to minimize risks.

- If you’re uncertain about any part of the process, consult a licensed electrician.

Proper installation of a grounding system not only ensures electrical safety but also protects your property and devices from unnecessary damage.

Benefits of Proper Grounding

Heading: Why Grounding Systems Matter

Subheading: Safety for People and Equipment

Proper grounding systems play a vital role in protecting both people and equipment. They provide a safe pathway for electrical faults, reducing the risk of electric shock and fire hazards. By diverting fault currents away from individuals and sensitive devices, grounding systems ensure the safety of electrical installations. This layer of protection is critical in preventing damage to expensive equipment caused by power surges or lightning strikes.

Subheading: Regulatory Compliance

Grounding systems are essential for meeting electrical safety codes and regulations. Most jurisdictions have strict guidelines, such as those outlined in the National Electrical Code (NEC), which mandate proper grounding to ensure safety. Non-compliance can lead to penalties, project delays, or even complete operational shutdowns. Adhering to these standards not only guarantees legal compliance but also instills confidence in the safety and reliability of electrical installations

Common Challenges and Solutions

Heading: Troubleshooting Grounding Systems

Subheading: Frequent Issues

Grounding systems, while crucial for safety, can face several common problems. Loose or faulty connections often occur due to improper installation or wear and tear over time, reducing system effectiveness. Corrosion of grounding electrodes or conductors, particularly in areas with high soil moisture or salinity, can also compromise the integrity of the system. Poor soil conductivity, caused by dry or rocky terrain, may hinder the grounding system’s ability to disperse fault currents effectively. These issues, if left unaddressed, can pose serious safety risks and undermine electrical system reliability.

Subheading: Solutions

Addressing grounding system challenges requires a combination of preventive measures and timely interventions. Ensuring secure and durable connections during installation is critical—using corrosion-resistant materials, such as copper or galvanized steel, can significantly extend system life. For areas with poor soil conductivity, enhancing the soil with conductive compounds or installing multiple grounding electrodes can improve performance. Regular inspections and testing help identify potential issues early, allowing for prompt maintenance or replacement of compromised components. By adhering to best practices, grounding systems can remain effective and compliant with safety standards

Advanced Topics in Grounding Systems

Heading: Beyond Basics: Specialized Grounding Applications

Subheading: Lightning Protection Systems

Lightning protection systems are critical in areas prone to thunderstorms. These systems work by safely directing high-energy lightning strikes into the ground, preventing damage to buildings and electrical equipment. A typical lightning protection system includes air terminals, grounding rods, and conductors designed to handle extreme voltage. Properly installed systems reduce the risk of fires and ensure the safety of occupants, making them an essential addition for commercial buildings, factories, and even residential properties in high-risk zones.

Subheading: Static and Equipment Grounding

Static grounding helps mitigate the accumulation of static electricity, which can cause sparks and pose fire or explosion risks, particularly in industries handling flammable materials. Equipment grounding, on the other hand, ensures the safe operation of machinery by providing a fault-current path, protecting both the equipment and the operator. These specialized grounding applications are essential in settings like manufacturing plants, laboratories, and warehouses, where sensitive equipment and volatile substances are often present

FAQs

What is the purpose of a grounding rod?

A grounding rod is a metal rod, usually made of copper or galvanized steel, driven into the ground to connect the electrical system to the earth. Its purpose is to safely disperse electrical fault currents or lightning strikes into the ground, protecting people and equipment from electric shock and damage.

Q: Can a grounding system fail? How to detect and fix it?

Yes, grounding systems can fail due to corrosion, loose connections, or damaged components. To detect issues, regular testing with grounding resistance meters is essential. If problems are found, replacing corroded parts, tightening connections, or improving soil conductivity can restore the system’s effectiveness.

Q: Is it safe to install a grounding system on your own?

Installing a grounding system requires technical knowledge to ensure safety and compliance with electrical codes. While basic systems can be DIY-friendly for skilled individuals, it is always advisable to consult or hire a licensed electrician for complex installations or to verify the work

Conclusion

In summary, grounding systems are crucial for electrical safety, ensuring protection against electrical faults, fires, and electrical shocks. Understanding the different types of grounding systems, installation methods, and maintenance practices is key to ensuring their effectiveness. Proper grounding also ensures compliance with electrical safety codes and helps protect valuable equipment.

While basic grounding systems can be managed with some knowledge, it’s always recommended to consult a professional electrician when in doubt. Ensuring your system is correctly installed and regularly maintained will safeguard both people and property from electrical hazards.