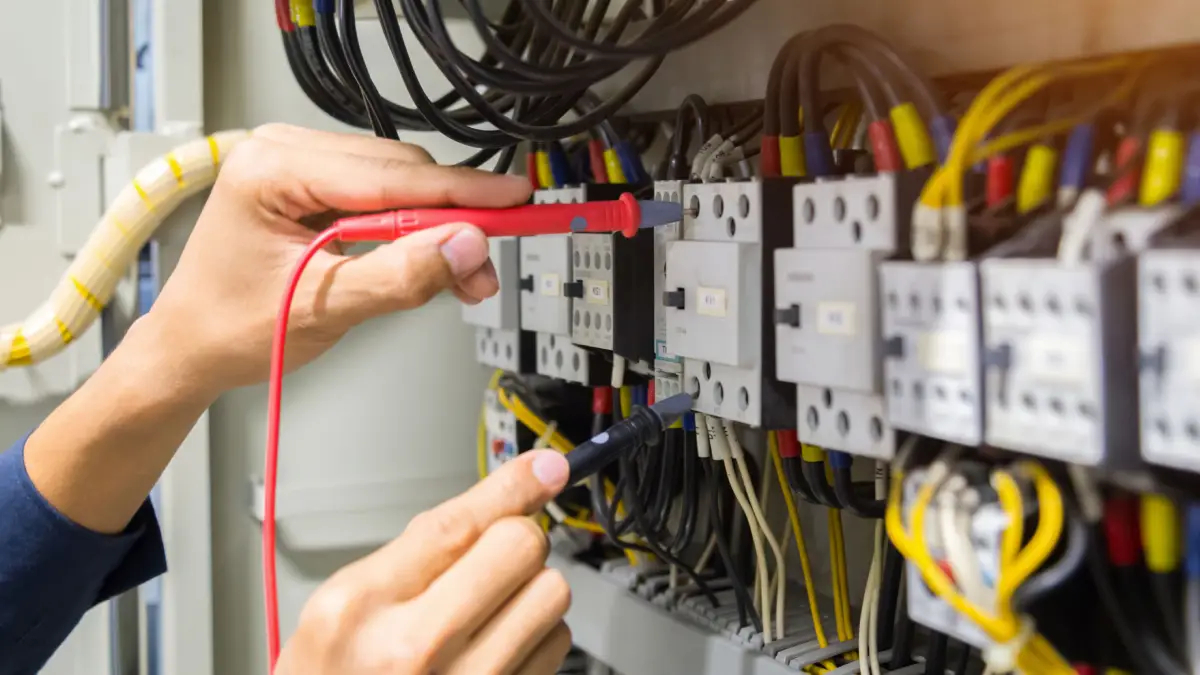

Guía Completa de Electricidad Residencial: Conocimientos Básicos y Mejoras Prácticas

Bienvenidos a la ‘Guía Completa de Electricidad Residencial: Conocimientos Básicos y Mejoras Prácticas’. Este libro se ha diseñado para proporcionarte una comprensión profunda de la electricidad residencial, los principios fundamentales que la rigen y las prácticas esenciales para mejorar la seguridad y eficiencia de las instalaciones eléctricas en nuestros hogares. No importa si eres un … Read more